Technical Urea

What is Technical Urea?

Technical urea is a refined form of urea with low biuret and impurities, making it suitable for precise industrial applications. With a nitrogen content of approximately 46%, it serves as a raw material in chemical synthesis, automotive emission control, and more.

How is Technical Urea Produced?

Technical urea is produced by reacting ammonia (NH₃) with carbon dioxide (CO₂) under high pressure and temperature. This reaction forms ammonium carbamate, which is then dehydrated to create urea.

2. Purification

For technical applications, the urea undergoes additional purification processes to reduce impurities such as biuret, heavy metals, and insoluble particles.

3. Forming

Technical urea is available in various forms, including prilled, granular, and liquid, depending on its intended application.

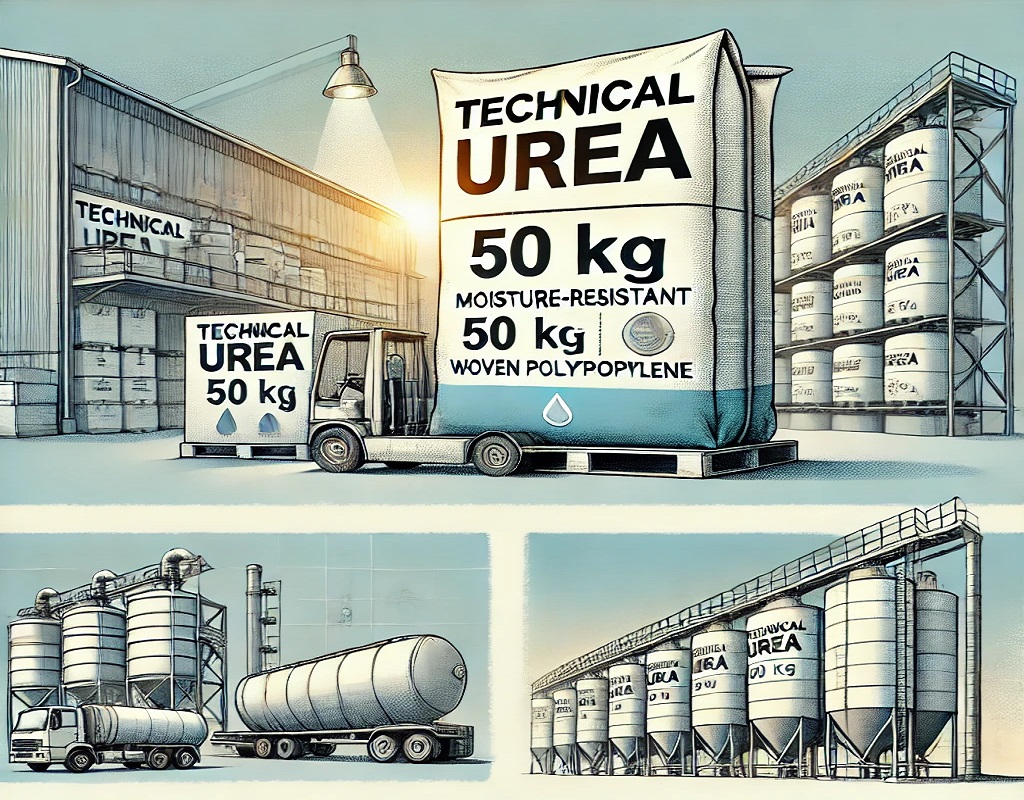

Packaging Options for Technical Urea

Proper packaging is crucial to maintain the quality and usability of technical urea, especially for industrial use. Common packaging options include:

1. Bags (25-50 kg)

- Technical urea is often packaged in smaller, moisture-proof bags for specialized applications.

- These bags are made from woven polypropylene with inner liners to prevent contamination.

2. Jumbo Bags (500-1000 kg)

- Large-scale industrial consumers prefer jumbo bags for efficient handling and storage.

3. Bulk Supply

- For high-demand sectors, technical urea is transported in bulk using tankers or containers, ensuring seamless delivery to industrial facilities.

Applications of Technical Urea

Technical urea serves as a raw material in the production of:

- Resins and Adhesives: Used to create urea-formaldehyde resins for wood products.

- Melamine Production: A critical component in manufacturing melamine for laminates and plastics.

2. Automotive Sector

- Emission Control (AdBlue/DEF): Technical urea is a key ingredient in diesel exhaust fluid (DEF) to reduce nitrogen oxide (NOx) emissions in vehicles using selective catalytic reduction (SCR) systems.

3. Environmental Applications

- Flue Gas Treatment: Used in power plants and industries to reduce NOx emissions.

- Water Treatment: Acts as a nutrient source in bioremediation processes.

4. Fertilizer Additive

While not a primary fertilizer, technical urea is blended into specialty fertilizers to provide consistent quality and performance.

5. Pharmaceutical and Cosmetic Uses

- In some cases, high-purity urea is used as a humectant in skincare products or in pharmaceutical formulations.

Advantages of Using Technical Urea

- High Purity: Meets stringent requirements for industrial and technical applications.

- Versatility: Suitable for a wide range of industries, from automotive to chemicals.

- Cost-Effective: Provides excellent performance at a competitive price.

- Environmental Benefits: Plays a critical role in reducing industrial and vehicular emissions.

Environmental Considerations

When using technical urea, it is essential to:

- Store Properly: Ensure the product remains dry and free from contaminants.

- Handle Responsibly: Avoid over-application in environmental or agricultural contexts to minimize nitrogen loss.

Technical urea is an indispensable product across industries, offering high purity and versatility for a variety of applications. From reducing emissions in vehicles to serving as a base material for chemical synthesis, its uses are vast and impactful. With proper packaging and handling, technical urea ensures consistent performance and contributes to sustainable industrial practices.