Table of Contents

ToggleWhat is Granular Urea?

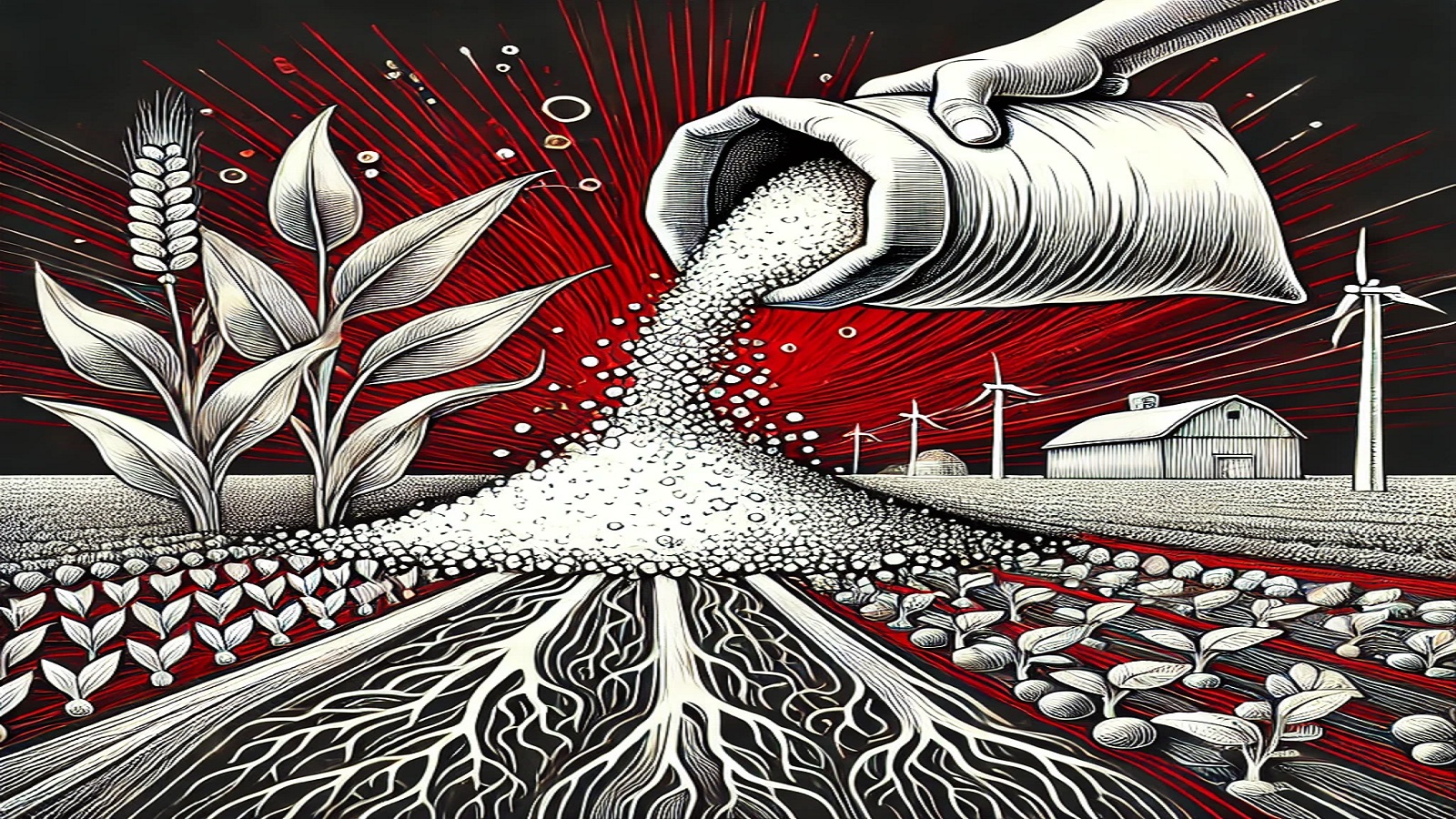

Granular urea is a solid nitrogen fertilizer with a 46% nitrogen content. Unlike prilled urea, granular urea features larger and harder granules, making it ideal for mechanical spreading and slow-release applications.

How is Granular Urea Produced?

1. Ammonia and Carbon Dioxide Reaction

The production begins with the synthesis of urea from ammonia (NH₃) and carbon dioxide (CO₂) at high temperatures and pressure. This reaction forms ammonium carbamate, which is then dehydrated to produce molten urea.

2. Granulation Process

The molten urea is sprayed onto a moving bed or tumbling granulator. During this process:

- Granules form as layers build up around nuclei (seed particles).

- The granules are dried, cooled, and hardened to ensure they can withstand storage and transportation without breaking.

3. Screening and Quality Control

Granules are sieved to ensure uniformity in size. Oversized granules are crushed and recycled, while undersized particles are returned to the granulator.

Pro Tip: Granular urea’s durable structure makes it ideal for modern farming equipment, enabling efficient application.

Packaging Options for Granular Urea

Granular urea is packaged to meet the requirements of diverse users, from small farmers to large industrial consumers:

1. Retail-Sized Bags (25-50 kg)

- These smaller bags are made of durable, moisture-resistant materials to protect the urea from clumping.

- Ideal for smaller farms or retail customers.

2. Bulk Bags (500-1000 kg)

- Commonly used in large-scale farming and industrial settings, these jumbo bags reduce handling costs and simplify logistics.

3. Bulk Transportation

- Granular urea is transported in bulk via ships, trains, and trucks, ensuring cost-effective delivery for large operations.

Applications of Granular Urea

Granular urea is primarily used as a nitrogen fertilizer to enhance soil fertility and crop growth. Its larger size allows for mechanical spreading, ensuring even coverage and reduced nitrogen loss.

2. Blended Fertilizers

It is often mixed with other nutrients to create customized fertilizer blends suited to specific crops and soil types.

3. Industrial Uses

Granular urea is used in various industrial applications:

- Adhesives and Resins: A raw material in producing urea-formaldehyde resins.

- NOx Emission Control: Acts as a reducing agent in selective catalytic reduction (SCR) systems for power plants and vehicles.

4. Environmental Applications

Granular urea is used in some environmental applications, such as odor control in waste treatment facilities.

Advantages of Granular Urea

- Durability: Granules are resistant to breakage, making them suitable for long storage and rough handling.

- Even Application: Uniform granule size allows for precise spreading with modern equipment.

- Slow-Release Capability: Provides a steady nitrogen supply over time, reducing the frequency of re-application.

- High Nitrogen Content: With 46% nitrogen, granular urea delivers maximum nutrient efficiency.

Environmental Considerations

To minimize nitrogen loss and environmental impact, granular urea should be applied correctly:

- Incorporation into Soil: Covering urea with soil reduces volatilization.

- Use of Urease Inhibitors: These slow down the conversion of urea to ammonia, enhancing nitrogen retention.

- Application Timing: Avoid applying urea before heavy rains to reduce leaching.

Granular urea is a versatile, high-performance fertilizer essential for modern agriculture and various industrial applications. Its production process ensures durability and uniformity, while its packaging and usage adaptability make it a favorite among farmers and industries alike.