Table of Contents

ToggleEPS (Expanded Polystyrene):

Types, Grades, Applications, and Benefits

Introduction

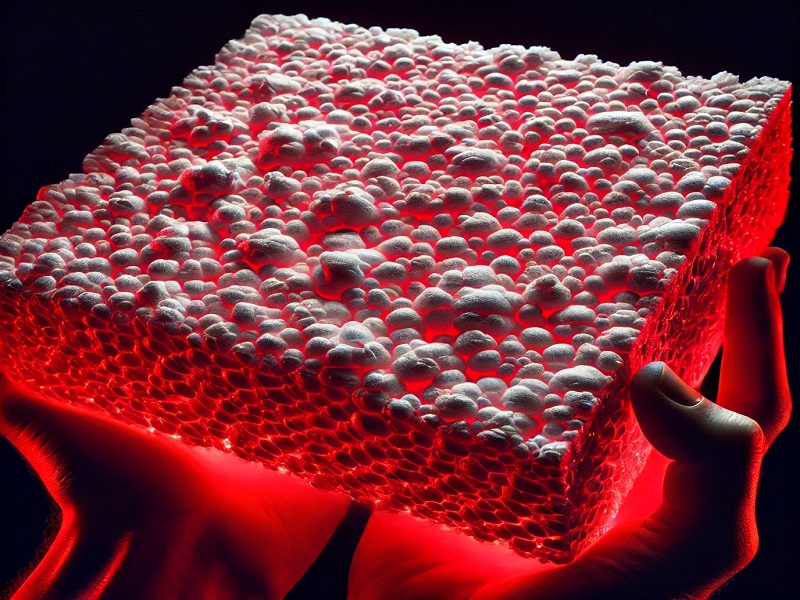

Expanded Polystyrene (EPS) is a lightweight and versatile thermoplastic material widely used in packaging, construction, insulation, and protective applications. Due to its excellent thermal insulation, shock absorption, and cost-effectiveness, EPS has become a preferred material across various industries.

What is EPS?

EPS is a rigid, closed-cell foam derived from polystyrene. It is produced by expanding polystyrene beads using steam and a blowing agent, resulting in a lightweight yet durable material with excellent insulating and protective properties.

Types of EPS

EPS is categorized based on density, processing method, and application:

1. Standard EPS (General-Purpose EPS)

- Lightweight and cost-effective

- Used in packaging, insulation, and disposable containers

2. High-Density EPS

- Greater strength and durability

- Ideal for construction panels, impact-resistant packaging, and automotive parts

3. Graphite-Infused EPS (Grey EPS)

- Enhanced thermal insulation

- Used in energy-efficient buildings and advanced insulation applications

4. Fire-Retardant EPS (FR-EPS)

- Improved fire resistance due to special additives

- Used in building insulation and fire-safe construction materials

EPS Grades and Their Applications

| Grade | Applications |

|---|---|

| Standard EPS | Disposable cups, food packaging, insulation panels |

| High-Density EPS | Protective packaging, automotive components, construction |

| Graphite-Infused EPS | Energy-efficient insulation, roofing, and wall panels |

| Fire-Retardant EPS | Fire-safe insulation for buildings and industrial applications |

Applications of EPS in Different Industries

1. Construction & Insulation

- Insulation boards for walls, floors, and roofs

- Lightweight concrete blocks for energy-efficient buildings

2. Packaging Industry

- Shock-absorbing packaging for fragile items (electronics, appliances, medical equipment)

- Food-grade packaging (fast-food containers, trays, and cups)

3. Automotive & Industrial Uses

- Impact-resistant panels for automotive safety

- Lightweight components for fuel efficiency

4. Consumer Goods & Decoration

- Craft and decoration materials

- Model-making and prototyping for architecture and engineering

Advantages of EPS

Disadvantages of EPS

EPS is a versatile and widely used material in packaging, insulation, construction, and industrial applications. Its lightweight nature, cost-effectiveness, and insulating properties make it an ideal choice for businesses looking for durable and efficient materials. However, ensuring proper recycling and sustainable usage is crucial for minimizing environmental impact.