Sulfur

Sulfur:

Types, Applications, and Industrial Importance

Introduction

Sulfur is a versatile chemical element used across multiple industries, including agriculture, pharmaceuticals, petrochemicals, and rubber manufacturing. It plays a critical role in fertilizer production, chemical synthesis, and fuel refining.

What is Sulfur?

Sulfur (S) is a non-metallic element found in natural deposits, crude oil, natural gas, and minerals. It is yellow, brittle, and odorless in its pure form but forms various compounds such as sulfuric acid (H₂SO₄), hydrogen sulfide (H₂S), and sulfates in nature.

Due to its reactivity and ability to form strong chemical bonds, sulfur is an essential component in many industrial and chemical processes.

Types of Sulfur

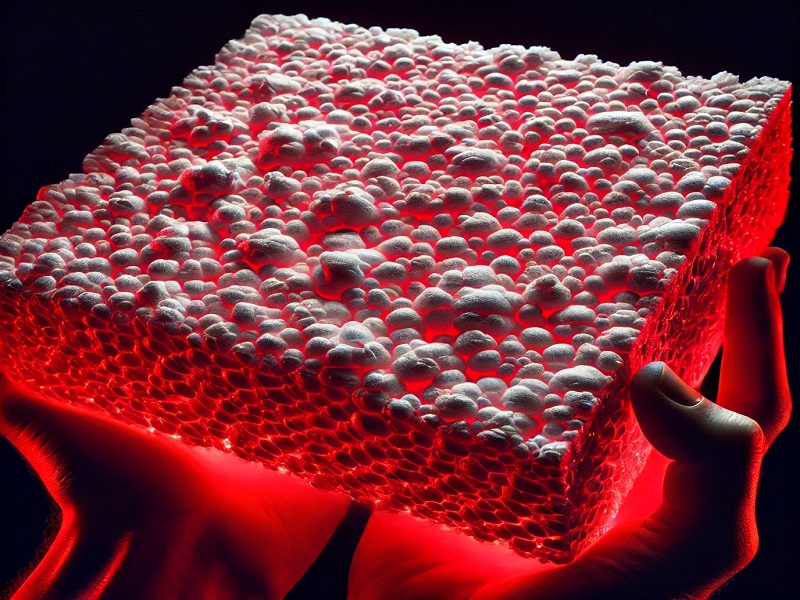

1. Elemental Sulfur (Pure Sulfur)

- Extracted from natural sources, volcanic deposits, or gas processing

- Used in fertilizers, fungicides, and chemical industries

2. Sulfur Compounds

Includes various forms such as:

- Sulfur Dioxide (SO₂) – Used in food preservatives, pulp and paper industry

- Sulfuric Acid (H₂SO₄) – Key component in fertilizers, batteries, and chemical production

- Hydrogen Sulfide (H₂S) – Found in crude oil and used in chemical manufacturing

3. Sulfur-Based Polymers

- Used in rubber vulcanization, synthetic fibers, and adhesives

4. Industrial By-Product Sulfur

- Extracted from refining crude oil and natural gas (Claus Process)

- Used in fuel desulfurization, asphalt production, and chemical industries

Applications of Sulfur

1. Fertilizer Industry

- Sulfur is an essential nutrient for plants, used in sulfate-based fertilizers (Ammonium Sulfate, Gypsum)

- Improves soil health and crop yield

2. Petrochemical Industry

- Desulfurization of fuels (removing sulfur to produce low-sulfur diesel and gasoline)

- Production of sulfur-based chemicals like sulfuric acid and sulfides

3. Rubber and Tire Manufacturing

- Vulcanization of rubber (strengthens rubber for tires, seals, and industrial components)

- Increases durability, elasticity, and heat resistance

4. Pharmaceuticals and Medical Applications

- Sulfur-based drugs (antibiotics, antifungal medications, and skin treatments)

- Used in allergy treatments and dermatological products

5. Metallurgy and Mining

- Extracting metals from ores (used in copper, lead, and zinc refining)

- Production of sulfuric acid for ore processing

6. Pulp and Paper Industry

- Bleaching agents in paper manufacturing

- Helps soften wood pulp for paper production

7. Food and Beverage Industry

- Sulfur dioxide (SO₂) is a preservative for dried fruits, wine, and canned foods

- Prevents oxidation and bacterial growth

Advantages of Sulfur in Industry

Enhances agricultural productivity (improves soil and crop quality)

Essential for fuel purification (removes harmful sulfur emissions)

Vital in rubber and plastic production (improves material strength)

Used in medicine (antibacterial and antifungal properties)

Cost-effective chemical with multiple industrial uses

Challenges and Environmental Considerations

Sulfur emissions contribute to acid rain (regulated by environmental laws)

Toxic gases like hydrogen sulfide require strict handling

Mining and extraction processes can cause pollution

Sustainable Sulfur Management

- Sulfur recovery units in refineries reduce emissions

- Recycling sulfur from industrial waste minimizes environmental impact

Sulfur is a crucial element with diverse industrial applications, from agriculture and fuel refining to pharmaceuticals and rubber production. Despite environmental challenges, industries are implementing sustainable sulfur recovery methods to minimize its impact.

Lightweight and easy to handle

Lightweight and easy to handle Non-biodegradable, requiring proper recycling methods

Non-biodegradable, requiring proper recycling methods