What is Diesel Exhaust Fluid (DEF)?

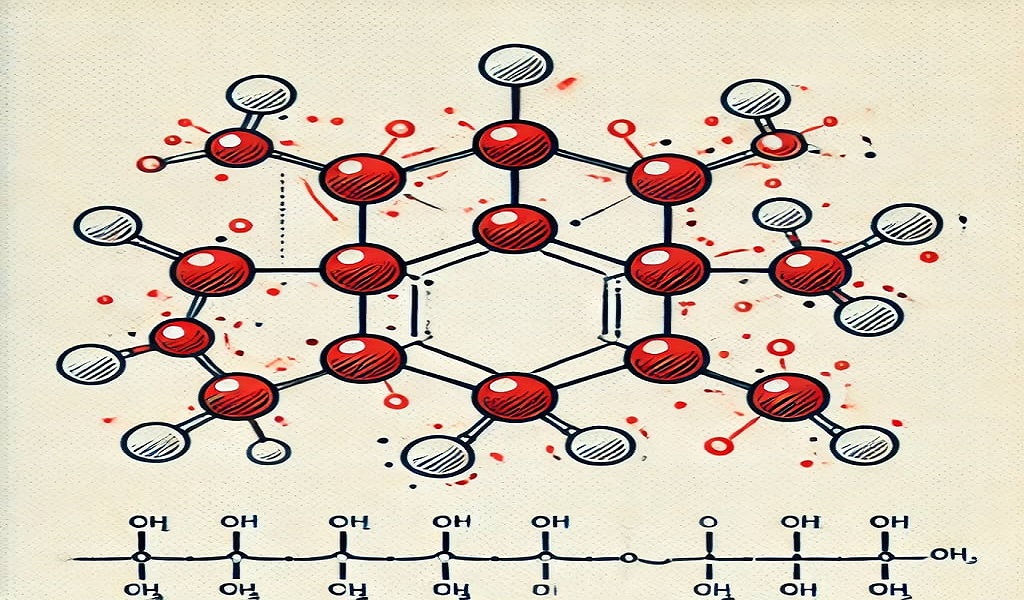

DEF is a non-toxic, colorless, and odorless liquid made from:

- 32.5% High-Purity Urea: A nitrogen-rich compound.

- 67.5% Deionized Water: Ensures purity and prevents contamination.

DEF is used in vehicles equipped with Selective Catalytic Reduction (SCR) systems to convert NOx emissions into harmless nitrogen and water vapor.

How Does Diesel Exhaust Fluid (DEF) Work?

- When the diesel engine runs, NOx gases are produced during combustion.

- DEF is sprayed into the exhaust system, upstream of the SCR catalyst.

2. Thermal Decomposition

- At high temperatures, DEF decomposes into ammonia (NH₃) and carbon dioxide (CO₂).

3. Catalytic Reaction

- In the SCR system, ammonia reacts with NOx gases.

- This reaction converts NOx into nitrogen (N₂) and water vapor (H₂O), both of which are naturally occurring and harmless.

Fun Fact: A single gallon of DEF can eliminate up to 90% of NOx emissions from a diesel engine.

Composition and Quality Standards

For DEF to function effectively, it must meet strict quality standards like ISO 22241. Using non-compliant DEF can damage the SCR system and void warranties.

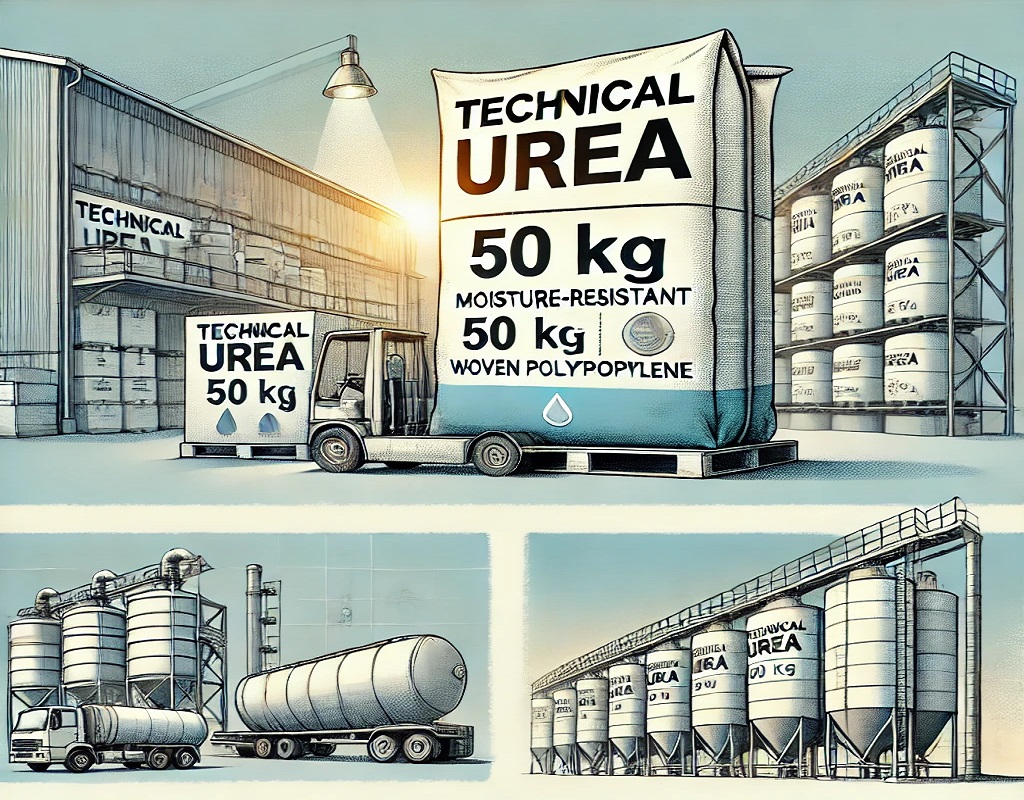

Packaging and Storage of DEF

DEF is packaged and stored to maintain its purity and effectiveness:

1. Small Containers (1-10 liters)

- Ideal for individual vehicle owners.

- Convenient, easy to store, and transport.

2. Medium-Sized Drums (20-210 liters)

- Used by small to medium-sized fleet operators.

3. Bulk Storage Tanks

- Designed for large-scale consumers, such as logistics companies or industrial facilities.

Pro Tip: DEF should be stored in a cool, dry place at temperatures between -11°C and 30°C to prevent freezing or degradation.

Applications of Diesel Exhaust Fluid

1. Automotive Sector

- DEF is commonly used in heavy-duty trucks, buses, and agricultural vehicles equipped with SCR systems.

2. Industrial Use

- Power plants and heavy machinery rely on DEF to reduce emissions and comply with environmental regulations.

3. Marine Applications

- Ships and marine vessels are increasingly adopting SCR systems with DEF to meet global emission standards.

Advantages of Diesel Exhaust Fluid

Environmental Benefits

- Reduces NOx emissions by up to 90%.

- Helps meet EPA and Euro 6 emission standards.

Improved Engine Efficiency

- SCR systems allow engines to run at higher combustion temperatures, improving fuel efficiency.

Compliance

- Essential for adhering to emission regulations in various industries.

Non-Toxic and Safe

- DEF is non-hazardous and easy to handle.

Environmental Impact

The use of DEF significantly reduces the environmental footprint of diesel engines by lowering NOx emissions, which contribute to smog, acid rain, and respiratory problems. It is a vital part of the transition to cleaner transportation and industrial practices.

Challenges and Best Practices

- Handling and Storage: DEF is sensitive to contamination. Use dedicated storage and dispensing equipment.

- Freezing Temperatures: DEF freezes below -11°C but remains usable after thawing.

- Quality Assurance: Always use certified DEF to protect the SCR system and engine warranty.