Table of Contents

ToggleWhat is High-Purity Urea?

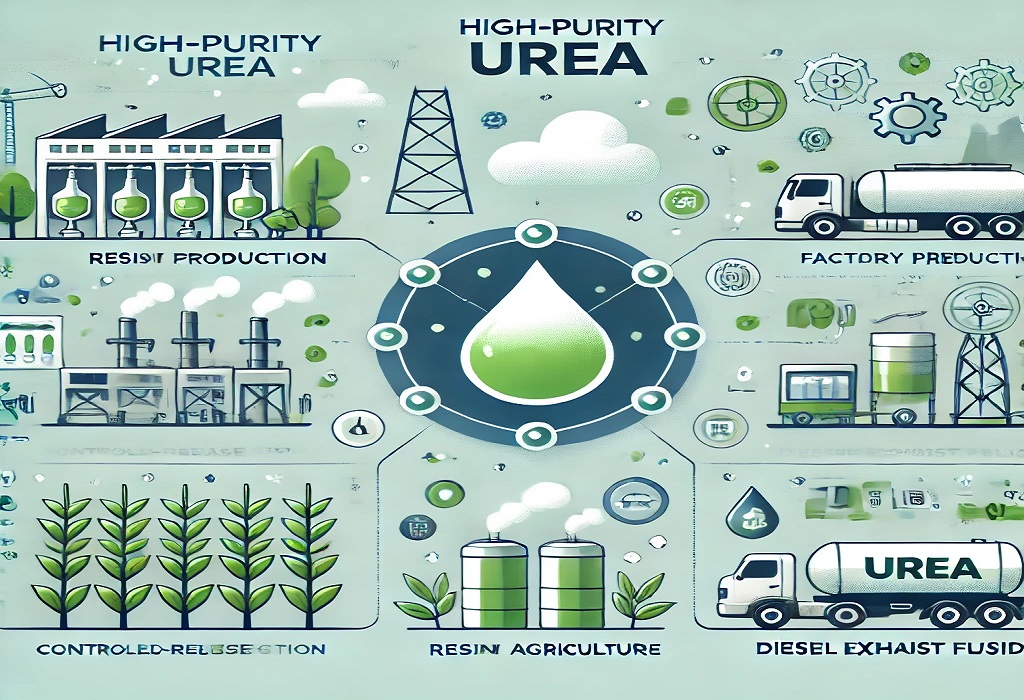

High-purity urea is a refined chemical compound derived from standard urea. By reducing impurities like biuret and heavy metals, it becomes suitable for critical chemical applications.

- Formula: CO(NH₂)₂

- Key Characteristics:

- High nitrogen content (46%).

- Minimal impurities for consistent performance.

- Soluble and stable under standard conditions.

Applications of High-Purity Urea in Chemical Production

High-purity urea is essential for producing urea-formaldehyde (UF) resins, widely used in:

- Laminates.

- Particleboard manufacturing.

- Molded plastic components.

Benefits:

- Ensures uniform product quality.

- Reduces production defects caused by impurities.

2. Pharmaceutical and Cosmetic Industries

- Used in the formulation of pharmaceutical intermediates and dermatological products, including moisturizers and ointments.

- High-purity urea enhances skin hydration and promotes healing.

3. Fertilizer Manufacturing

High-purity urea is a key ingredient in:

- Controlled-release fertilizers for efficient nutrient delivery.

- Foliar sprays for rapid absorption in crops.

Advantages:

- Increases crop yield.

- Minimizes nutrient leaching into water systems.

4. Diesel Exhaust Fluid (DEF) Production

High-purity urea is critical for DEF, a solution that reduces nitrogen oxide (NOx) emissions in diesel engines using SCR (Selective Catalytic Reduction) systems.

Advantages of Using High-Purity Urea

The low impurity levels in high-purity urea ensure reliable performance in sensitive chemical processes.

2. Cost Efficiency

With fewer impurities, manufacturers achieve higher efficiency, reducing waste and production costs.

3. Environmental Sustainability

- In DEF production, urea reduces harmful emissions.

- Controlled-release fertilizers minimize runoff, supporting sustainable farming practices.

4. Broad Applicability

High-purity urea is adaptable across multiple industries, making it a versatile choice for chemical producers.

Challenges in High-Purity Urea Production

Urea production relies on energy-intensive processes, especially for impurity reduction.

Solution: Transition to renewable energy sources in ammonia production.

2. Handling and Storage

Improper storage can lead to moisture absorption and reduced effectiveness.

Solution: Use advanced packaging and climate-controlled storage facilities.