Table of Contents

ToggleMDPE:

Types, Grades, Applications, and Advantages

Introduction

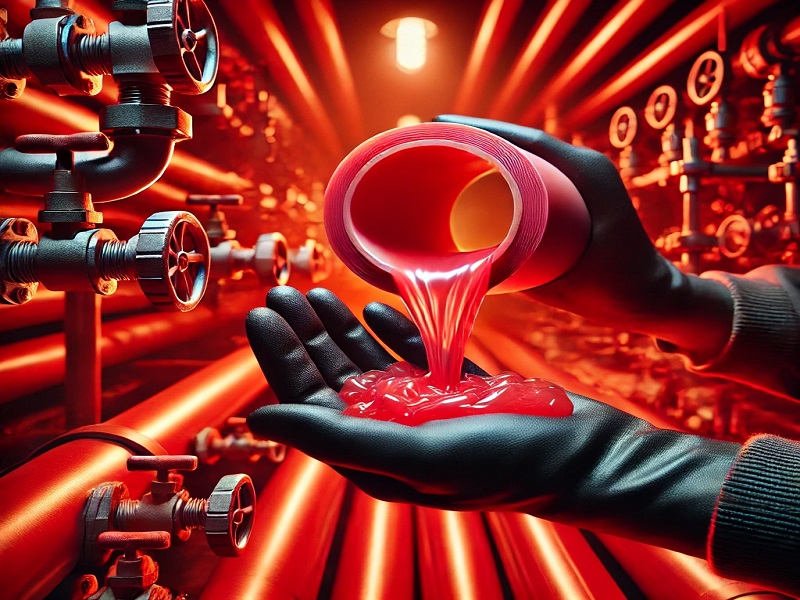

Medium-Density Polyethylene (MDPE) is a versatile thermoplastic that balances the flexibility of LDPE and the strength of HDPE. It is widely used in piping systems, packaging, industrial containers, and gas distribution networks.

What is MDPE?

MDPE is a polyethylene polymer with a density range between 0.926 – 0.940 g/cm³. It offers high impact resistance, good chemical stability, and excellent stress crack resistance, making it an ideal material for pipes, tanks, and industrial applications.

Types of MDPE

MDPE is categorized based on its polymerization process and molecular structure:

1. Gas Pipe Grade MDPE

- Highly durable and pressure-resistant

- Used in gas and water distribution pipelines

2. Rotomolding Grade MDPE

- Good toughness and impact resistance

- Ideal for storage tanks, road barriers, and large containers

3. Injection Molding Grade MDPE

- High rigidity and strength

- Used for industrial fittings, caps, and closures

4. Film Grade MDPE

- Flexible and lightweight

- Used in packaging films, shrink wraps, and protective covers

MDPE Grades and Their Applications

| Grade | Applications |

|---|---|

| Pipe Grade | Gas pipes, water distribution pipelines |

| Rotomolding Grade | Water tanks, road barriers, industrial storage |

| Injection Molding Grade | Fittings, caps, closures, industrial components |

| Film Grade | Packaging films, agricultural covers, shrink wraps |

Applications of MDPE in Different Industries

1. Piping & Infrastructure

- Gas distribution pipes due to their excellent pressure resistance

- Water supply systems for municipal and industrial use

2. Industrial Storage & Containers

- Rotationally molded tanks for chemical storage and water storage

- Barrier materials such as roadblocks and traffic cones

3. Packaging & Film Applications

- MDPE films for flexible packaging in food and consumer goods

- Shrink wraps for industrial and commercial products

4. Automotive Industry

- Fuel tanks and fluid storage components

- Protective covers for wiring systems

Advantages of MDPE

Better flexibility than HDPE but with improved toughness

High impact resistance and durability

Excellent chemical and corrosion resistance

Better stress crack resistance than standard PE materials

Lightweight and cost-effective for industrial applications

Easier processing compared to HDPE

Disadvantages of MDPE

Lower stiffness than HDPE, making it unsuitable for some rigid applications

Limited high-temperature resistance compared to engineering plastics

Requires UV stabilizers for prolonged outdoor exposure

Conclusion

MDPE is a highly durable and flexible thermoplastic used in a variety of industries, from gas pipelines to packaging and industrial storage tanks. Its unique properties make it an excellent alternative to both LDPE and HDPE, depending on the application requirements. With its growing use in infrastructure, automotive, and packaging sectors, MDPE continues to be a preferred material for manufacturers worldwide.