What is LDPE?

Types, Grades, and Applications

Introduction Low-Density Polyethylene (LDPE) is one of the most widely used industrial polymers due to its high flexibility, excellent chemical resistance, and easy processability. In this article, we will explore the types of LDPE, its grades, applications, advantages, and disadvantages, providing you with comprehensive information.

Table of Contents

ToggleLDPE Characteristics

High flexibility and good impact resistance

Chemical resistance, making it non-reactive with many acids and bases

Easy processability for manufacturing various plastic products

Relative transparency, allowing its use in different packaging applications

High resistance to cracking

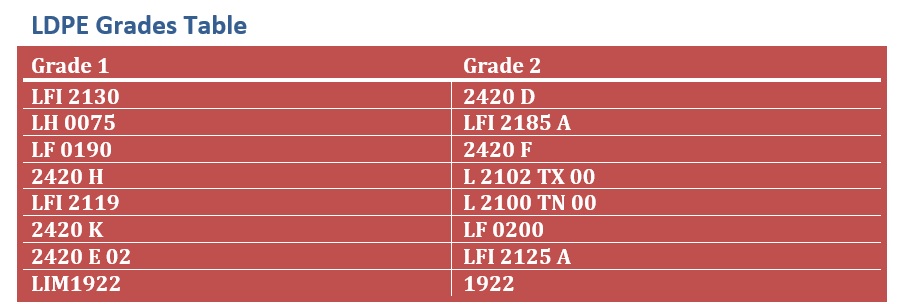

LDPE Grades and Applications

LDPE is available in various grades, each designed for specific applications:

1. General Purpose LDPE

Used in plastic bags, food packaging, and stretch films

2. Injection Molding LDPE

Applied in bottle caps, plastic containers, and industrial parts

3. Extrusion LDPE

Used for making plastic films, flexible pipes, and wire and cable coatings

4. Blow Molding LDPE

Suitable for manufacturing lightweight plastic bottles, storage containers, and plastic tanks

5. Coating Grade LDPE

Used in paper laminates, moisture-resistant packaging, and protective coatings

Applications of LDPE in Various Industries

Thanks to its diverse physical and chemical properties, LDPE is widely used in multiple industries:

Packaging: Plastic bags, protective films, and food packaging

Agriculture: Greenhouse films, irrigation pipes, and ground covers

Construction: Waterproof membranes, wire and cable coatings, and flexible pipes

Medical Industry: Disposable syringes, pharmaceutical packaging, and medical supplies

Automotive Industry: Interior vehicle components and waterproof materials for insulation

Advantages of Using LDPE

High flexibility and impact resistance

Low production cost compared to other plastics

Recyclability, reducing environmental impact

Good chemical resistance against many acids and bases

Disadvantages of LDPE

Low heat resistance, causing deformation at high temperatures

Sensitive to UV radiation, leading to degradation over time

Permeability to certain gases, which can be problematic for some packaging applications

Lower mechanical strength compared to polymers like HDPE